How to Build a Soundproof Room

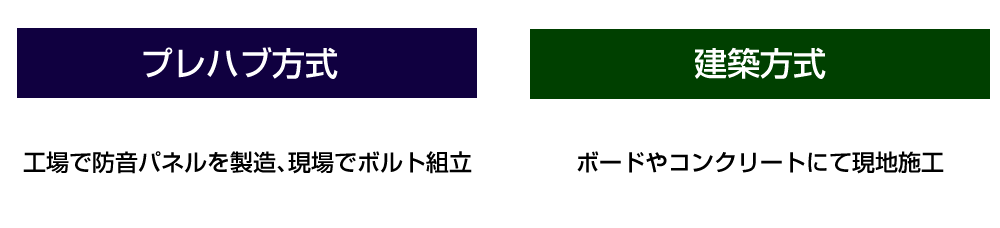

The methods for constructing a soundproof room vary by company, but they are generally divided into “modular” and “built-in” types.

Advantages & Disadvantages

| Modular Type | Built-in Type | |

|---|---|---|

| Cost | Material cost is high, but total cost is lower | Material cost is lower, but total cost is higher |

| Performance | Varies by company technology | Varies by company technology |

| Wall Thickness | Thinner walls, space-saving | Thicker walls, takes up more space |

| Dimensional Precision | Can be manufactured with millimeter precision | Depends on the skill of the workers |

| Relocation | Relocatable | Requires dismantling and reinstallation |

| Construction Time | Short on-site construction time | Long on-site construction time |

*This information is based on our research. If you have any questions, please contact us.

Since 2000, modular soundproof rooms and anechoic chambers using soundproof panels have become mainstream in the industrial soundproofing industry. Japanese clients often prioritize space efficiency, relocatability, and affordability, which modular systems address. In the early 2000s, modular soundproofing technology was not yet fully developed, and it could not match the soundproofing performance of concrete structures. However, with advancements in technology, the perception that built-in structures were the only solution was overturned. Soundproof panels as soundproof walls became prevalent, and now many overseas manufacturers also adopt modular designs.

Regulations for Installing Soundproof Rooms

In Japan, the Building Standards Act applies, and in most cases, compliance is required for installing soundproof rooms. This means that materials and the structure of soundproof rooms must meet standards for non-combustibility and, in some cases, fire resistance (interior restrictions). Commonly, non-combustible materials include stone, steel, and concrete. For the interior walls of soundproof rooms, sound-absorbing materials are often installed, but non-combustible sound-absorbing materials are limited. While rock wool and glass wool are non-combustible, urethane foam and melamine foam are not. Some overseas manufacturers may not be aware of these interior restrictions, resulting in issues with non-compliant designs, so caution is advised.

*This information is based on our research. If you have any questions, please contact us.

● Please also check out the following content