Does the Thickness of Sound-Absorbing Materials Directly Impact Effectiveness? Discover the Surprising Truth!

Flat-Panel Lamination vs. Acoustic Wedges! Advancements in Sound-Absorbing Materials Transform Anechoic Chambers

Designing Sound-Absorbing Materials requires setting the appropriate thickness according to the target frequency to absorb sound. For instance, to absorb a 500Hz sound, a thickness of 170mm, equivalent to one-quarter of the wavelength, is theoretically required. However, simply increasing thickness does not guarantee ideal absorption across all frequencies.

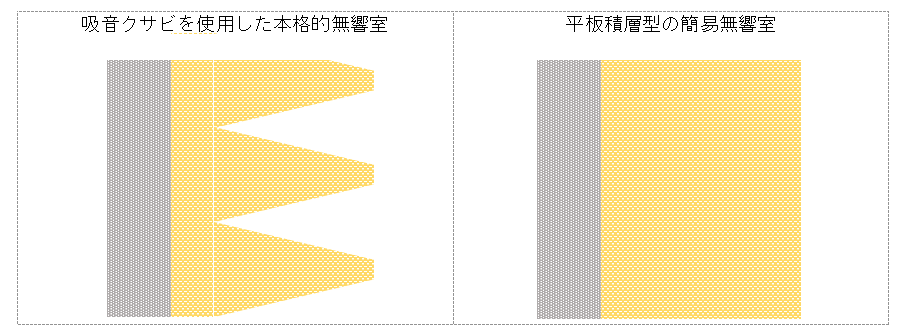

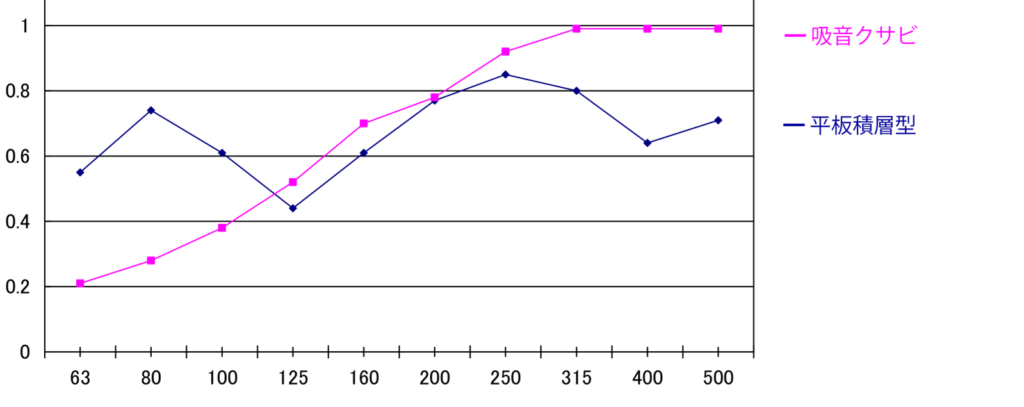

Differences Between Flat-Panel Lamination Chambers and Acoustic Wedges

Traditional anechoic chambers utilize acoustic wedges with a triangular shape, known for their ideal structure that minimizes sound reflections. However, their high cost has led to the development of flat-panel laminated chambers as a simpler alternative. Flat-panel lamination uses stacked sound-absorbing boards to increase thickness but exhibits imbalanced performance for specific frequencies and lower absorption efficiency at high frequencies compared to acoustic wedges.

Challenges with Flat-Panel Lamination and the Path to Improvement

Flat-panel laminated chambers demonstrate high absorption rates for specific frequencies but lack overall balance. A significant issue is their inability to achieve an absorption rate of 1 for high-frequency sounds with short wavelengths.

Vertical Incidence Absorption Rate Data: Comparison Using Identical Materials and Thickness

The use of acoustic wedges in anechoic chambers is attributed to their triangular shape, which optimizes sound absorption. This demonstrates that merely increasing the thickness of sound-absorbing materials does not suffice.

The Birth of a New Sound-Absorbing Material

To address these challenges, Sonora Technology has been developing new sound-absorbing structures surpassing acoustic wedges since 2009. This effort has culminated in the creation of innovative materials that revolutionize anechoic chamber performance.

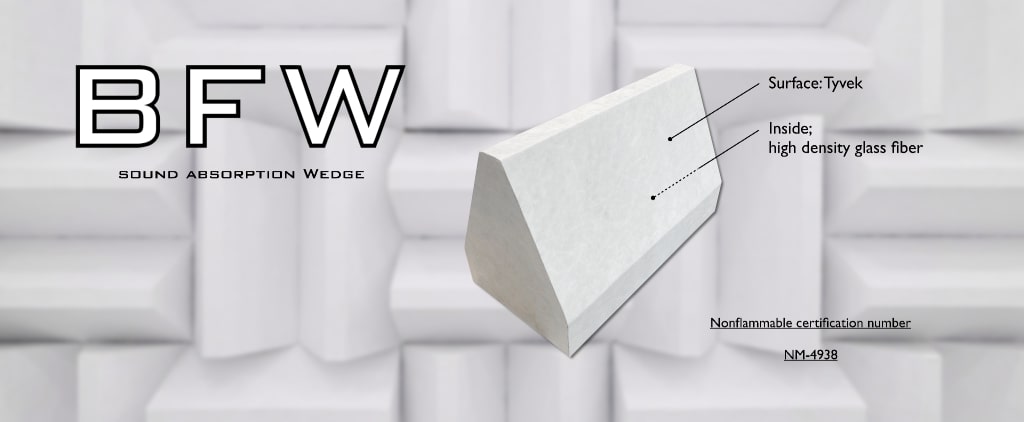

BF Series: Next-Generation Sound-Absorbing Materials

The Secret to Enhanced Absorption Rates

Sound absorption involves converting sound energy into heat energy. Improving this conversion efficiency can enhance absorption rates, but the performance of individual sound-absorbing materials has its limits. The key lies in optimizing the design and structure of the entire anechoic chamber. The new BF Series (BFW) material is developed with this perspective, promising to establish a new standard in anechoic chambers.

Summary

- Thickness alone does not maximize sound absorption effects.

- New materials and design structures offer potential to surpass acoustic wedges.

- Sonora Technology’s BF Series introduces a new trend in anechoic chamber technology.

Innovative sound-absorbing materials are transforming the performance of anechoic chambers!