JIS T 1201 and ISO 8253: Design Standards for Hearing Test Environments ─ Building Quiet Spaces That Ensure Medical Accuracy ─

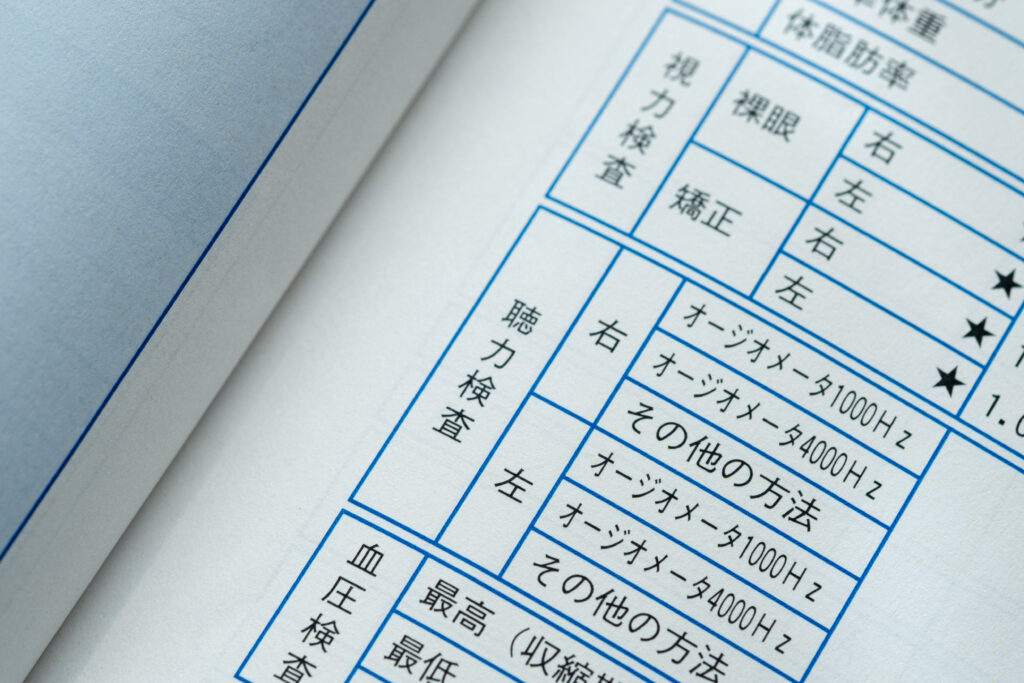

Introduction | Why Acoustic Environments Matter in Hearing Tests

Hearing tests play a vital role in diagnosing age-related, sudden, and noise-induced hearing loss, as well as in the fitting of hearing aids. The accuracy of these tests depends heavily on whether they are performed in an appropriately quiet environment.

This article focuses on the international and domestic standards—ISO 8253-1 and JIS T 1201-3—to explain the design requirements for hearing test rooms as acoustic environments.

1. ISO 8253-1:2010 and the Numerical Basis for “Silence”

ISO 8253-1 defines procedures for pure-tone audiometry and emphasizes that ambient noise must not interfere with the subject’s hearing threshold measurements.

● MPANL: Maximum Permissible Ambient Noise Level

The standard specifies MPANL values by 1/3-octave band, depending on the type of transducer used (headphones, insert earphones, etc.).

Example: MPANL when using TDH-39 headphones

| Frequency (Hz) | Max Noise Level (dB SPL) |

|---|---|

| 125 | 45 |

| 250 | 40 |

| 500 | 35 |

| 1000 | 30 |

| 2000 | 30 |

| 4000 | 35 |

Meeting these stringent values requires soundproof construction, as standard architectural materials alone are insufficient.

2. JIS T 1201-3:2017 and Domestic Environmental Standards

In Japan, the corresponding standard is JIS T 1201-3: Audiometers — Part 3: Test Methods for Hearing Aid Fitting.

This standard’s Appendix A outlines allowable ambient noise levels per frequency, similar to ISO 8253. In addition, JIS includes detailed methods for measuring noise and managing the test environment, placing emphasis not only on device performance but also on installation conditions.

3. Acoustic Design Elements Required in Real-World Applications

Based on these standards, hearing test environments must meet the following acoustic conditions:

(1) Sound Insulation: Isolating External Noise

-

Sound insulation rating D-50 or higher is generally required.

-

For steel or reinforced concrete structures, double walls and acoustic doors are standard.

-

Openings such as vents and cable ports must be acoustically sealed.

(2) Sound Absorption: Controlling Internal Reflections

-

Interior reflections must be minimized to ensure clear test tones.

-

The BF Series of absorptive materials from Sonora Technology Co., Ltd. (including BFW, BFB, and BFP) offers a sound absorption coefficient ≥ 0.99, creating a quiet and stress-free environment.

(3) Ambient Noise Control: Managing Testing Conditions

-

Room background noise must be measured and managed, targeting K2 ≤ 2 dB.

-

It must be verified that ambient noise does not exceed MPANL limits at any frequency band.

4. Enclosure’s Engineering Support and Project Experience

Enclosure Co., Ltd. specializes in constructing high-performance hearing test environments in full compliance with ISO and JIS standards.

◎ Our Services:

-

Acoustic surveys based on ISO 8253 and JIS T 1201

-

Design and construction of fully enclosed or modular rooms

-

Optional integration of BF Series by Sonora Technology for high-efficiency sound absorption

◎ Example Applications:

-

Hospitals and ENT clinics

-

Occupational health screening centers

-

Hearing aid retailers and training facilities

Conclusion | Quiet Design is the First Step Toward Accurate Testing

“Silence” is not just a comfort feature—it’s a technical prerequisite for accurate hearing tests.

JIS T 1201 and ISO 8253 provide the quantitative foundations for creating those acoustically valid conditions.

At Enclosure, we offer tailored acoustic solutions backed by real-world measurements and compliance with global standards.

Let us help you build testing environments that deliver on precision, safety, and comfort—all in one soundproof package.